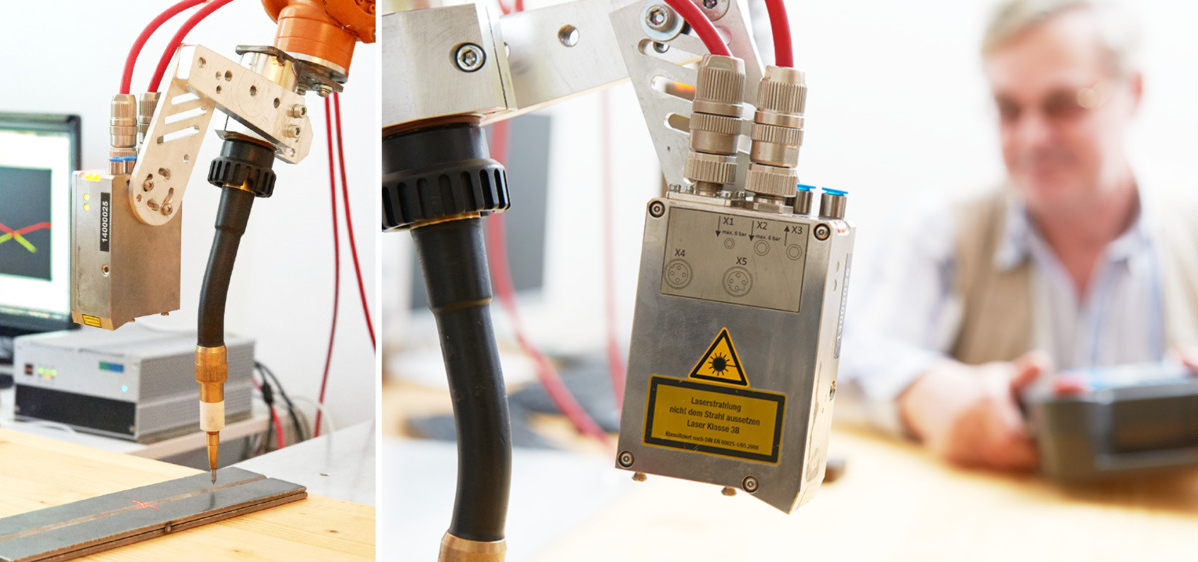

Seam tracking systems LASERGUIDE

The main purpose of these systems is online tracking to compensate tolerances and part movements caused by thermal influence.

These universal systems allow detecting work pieces' orientation in 3D, which is usable for handling and welding applications as seam tracking, inspection and adaptive control / welding.

materials

Steel, aluminum, titanium, NiRo, ...

processes

Single-wire / two-wire Mig / Mag steel, single-wire / two-wire Mig Aluminum, TIG, plasma welding or soldering

Sensors

- Field of view: 105 - 195 mm

- Measure width: 55mm

- Image generation rate: 60 Hz

- Accuracy: better 0.1mm

- Chip dynamic: 120dB

- Laser power: 50mW max

- Protection: IP64

- Laser class: 3B

- Dimensions: 100x70x40 mm

- Field of view:: 138 - 162 mm

- Measure width: 15 mm

- Image generation rate: 60 Hz

- Accuracy: better 0.03 mm

- Chip dynamic: 120 dB

- Laser power: 50 mW max

- Protection: IP64

- Laser class: 3B

- Dimensions: 100x70x40 mm

Our LASERGUIDE sensors are designed for the harsh welding environment and are unsensitive against smoke and spatters. Even the arc has no influence on the measurements reliability. These sensors, designed by and produced especially for us, actually really work.

Applications

Any seam shape can be recognized, and it's possible to correct the robot path. This allows the correct detection of components with high tolerances or of seam geometries with considerable changes in appearance over the course to be welded, as well as it ensures constant seam appearance. If the gap or edge offset is too large, the welding process can be stopped, for example.Properties

- Usable on difficult surfaces like Aluminium or stainless steel

- Very good price / performance ratio

- Web Interface for programming and monitoring (WiFi access possible)

- Recognition of any shape or joint

- Usable with robots or Cartesian (slides) systems

- Small dimensions, big stand off -- better accessability

- High chip dynamic (120dB) and laser power (50mW)

- Cable directly connected on the camera head

- Up to 50m cable length without an amplifier

- Cleaning air connector on the camera head

- Exchangeable protection glasses